- SureHeat Standard Gas Heaters

- …

- SureHeat Standard Gas Heaters

- SureHeat Standard Gas Heaters

- …

- SureHeat Standard Gas Heaters

Combustion Research

Fuel Cell R&D

Pollution Control

Renewable Energy

TUTCO SureHeat is focused on engineering customized solutions

for demanding process heating applications.

Maintenance Repair and Overhaul (MRO)

Aerospace Valve and Component Testing

Turbo Machinery

Wind Tunnel

High-temperature & high-pressure custom process heating

solutions for precise and durable performance.

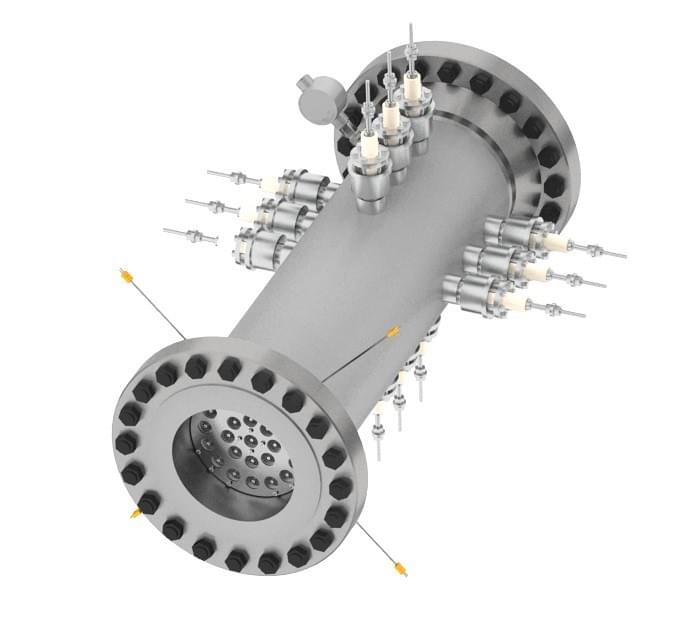

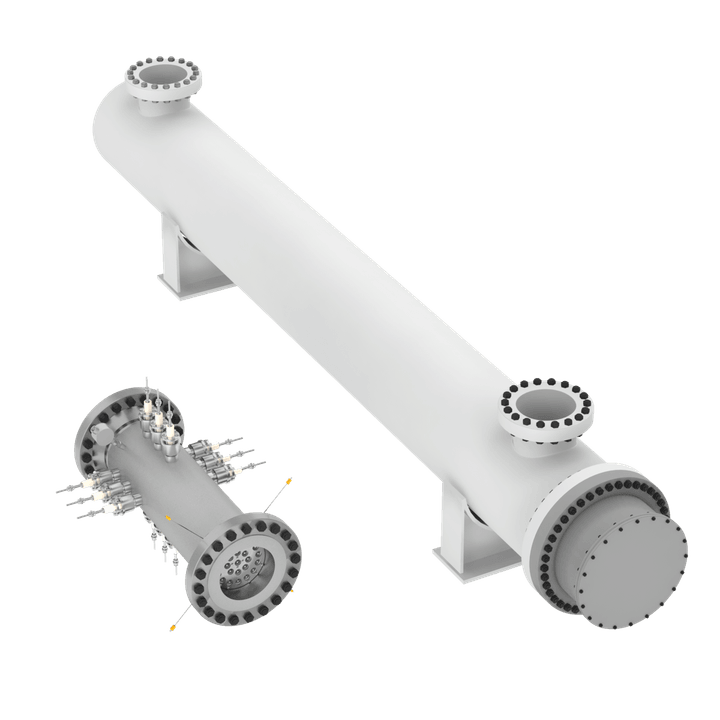

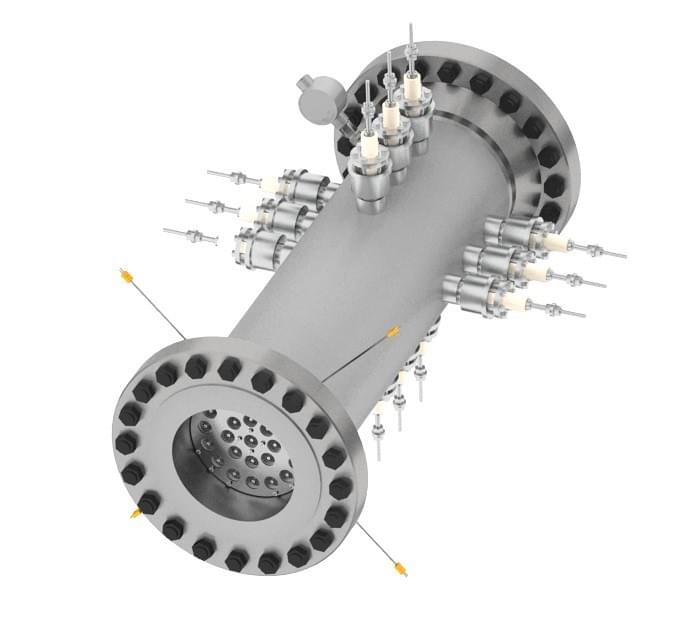

Specialty Flanged Inline Heaters

High-temperature & high-pressure custom process heating solutions for precise and durable performance.

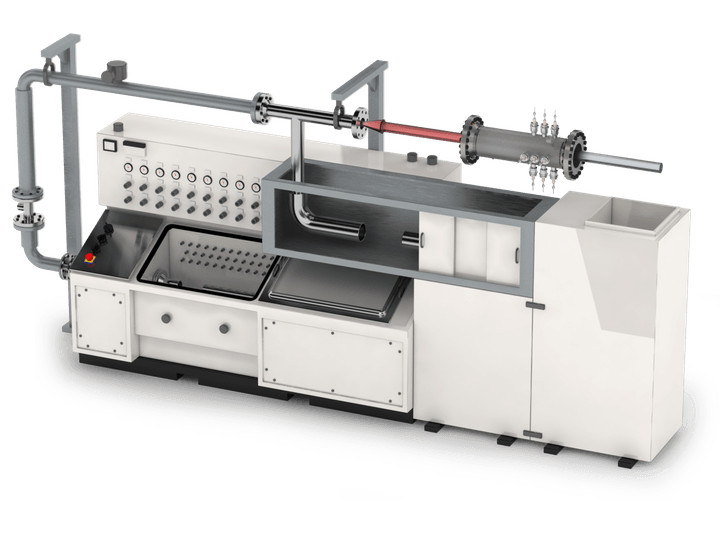

The TUTCO Advantage

The growing demand for efficient engines, reduced emissions, and renewable energy has driven the need for advanced testing and research involving high-temperature, high-pressure gas streams. Tutco SureHeat’s Specialty Flanged Inline (SFI) Heaters provide a reliable solution, offering safe, precise, and durable performance in demanding applications that require high temperatures, high pressures, and low flow rates. Designed to meet specific requirements, SFI heaters are fully customizable, ensuring they deliver tailored, effective heating solutions for your unique needs.

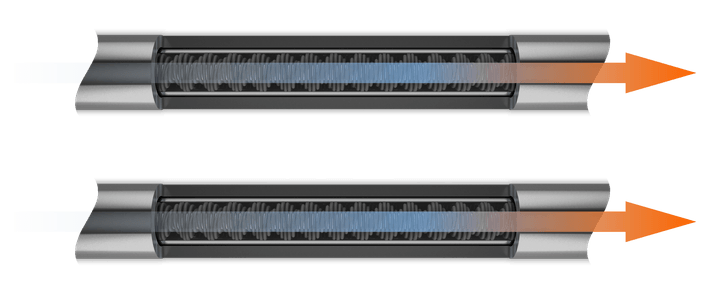

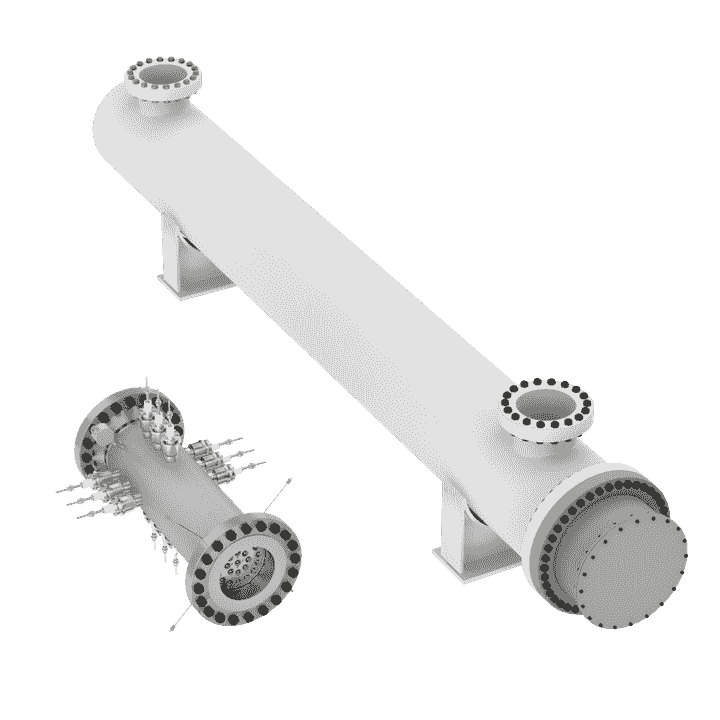

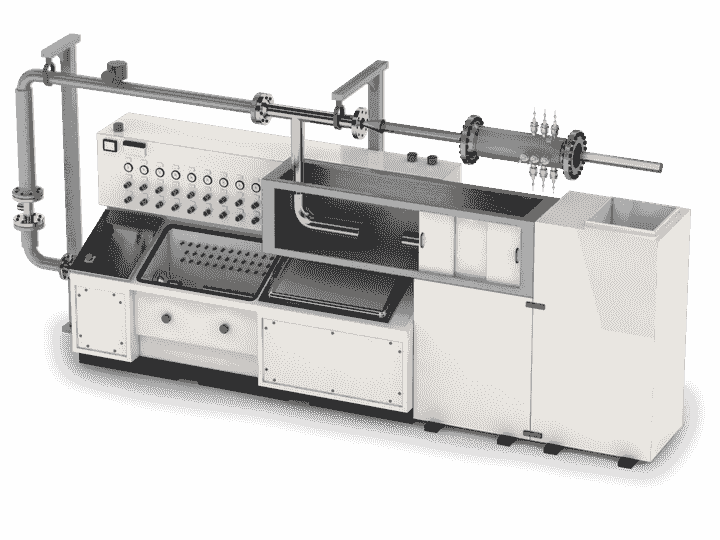

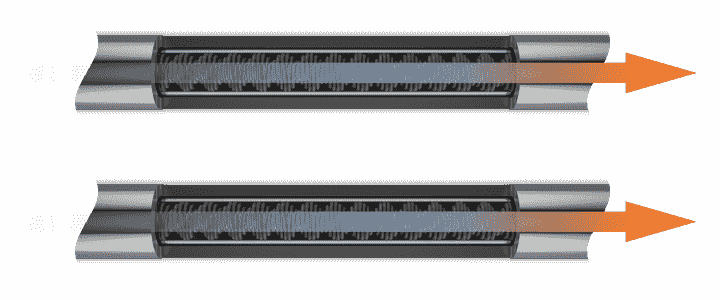

TUTCO SureHeat Specialty Flanged Inline (SFI) heaters offer superior performance over conventional sheathed (“tubular” or “immersion”) style heaters because they are designed specifically for air and inert gas applications, including hydrogen, CO2, steam, and syngas. Our proprietary SERPENTINE™ technology facilitates a very high power watt density creating a compact overall heater design. SFI heaters can be as much as 8-12X smaller than equivalent tubular/immersion designs. (see the diagram below) With this advantage, less space is required. With a faster heat-up and cool-down ramp time SFI electric air heaters are more cost effective to operate. Whether for a research test stand, factory production line, or key component in a product or thermal energy storage system, our Specialty Flanged Inline heater and controls are the right process heating solution for the job.

Key Features

- Designed for High Temperature Process Heat Applications using Air or Inert Gases, including hydrogen, CO2, steam, and syngas.

- Compact in Size and Weight Compared to Competitive Immersion Solutions

- Faster Temperature Ramp Rates are more Cost Effective to Operate

- Electric Control Panels Engineered Specifically for Each Application

Applications

- Combustion experiments

- Aircraft engine test benches

- Valve tests for aircraft maintenance, overhaul and repair equipment

- High-temperature fuel cell test benches

- Pollution control of nitrogen oxides, SCR (selective catalytic reduction reaction) tests

- High-temperature furnaces

- Pyrolysis applications

- Waste-to-energy processing

Specifications

- Maximum Static Pressure:3000 PSI (207 Bar)

- Maximum Inlet Temperature:900°F (482°C)

- Standard Outlet Temperatures:1922°F (1050°C)

- Temperature Control:+/- 2°F (+/-1°C)

- Ramp time:200°C per second

- Maximum Power Rating:100 MW and higher